There are so many technological advances in the world of printing these days, from 3D printing, from new innovations in digital printing, from nanographic printing to the explosion of online printing companies like ColorCopiesUSA, the industry is as viable as ever.

Initially however, the printing process was very tedious and time consuming. With the invention of movable parts, printing machines revolutionized the printing process. It facilitated faster and better printing which helped to spread knowledge and education around the world. Nowadays, the printing process has improved considerably due to technological advancement. Mass publications are made within a short time while still maintaining quality. Here are some of the common printing techniques used today.

Offset Lithography

It is one of the commonly used techniques in the printing industry. In this process, the content to be printed is contained on a printing plate. The plate has been designed to hold ink only on the part that contains the content. The inked part is transferred/offset to a rubber blanket and then on a printing surface. Modern offset printing machine uses computer systems to enhance quality. It is used to print any flat surface such as papers, plastic, etc. The most significant benefit of this technique is that it is cost effective and produces high-quality content. However, omissions cannot be corrected once the plates are set.

Flexography

Flexography is a commonly used printing technique used to customize content at rapid speeds. It is closely related to the traditional letterpress printing and is used in almost any type of surface. This technique utilizes flexible photopolymer printing plates that are attached on rotating cylinders. The plates are slightly raised and rotate at high speed to transfer the content on the printing surface. Flexography was extensively used in the 20th century in food packaging.

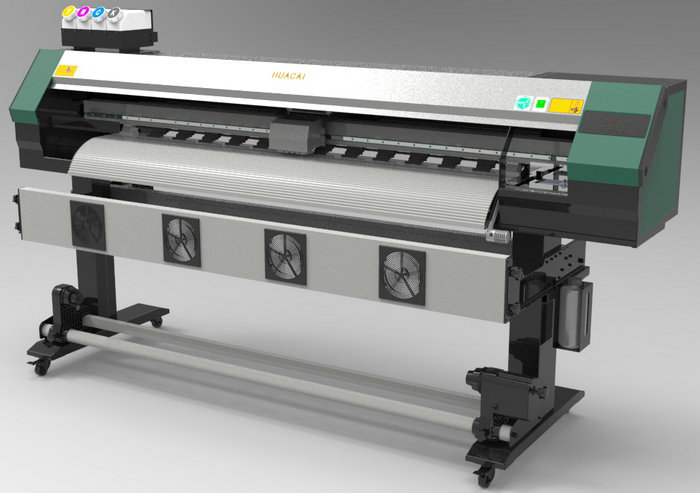

Digital Printing

Recently, digital printing has become popular due to the advancement of technology. The technique involves transferring content from a digital device to a printing surface. Unlike other traditional methods such as lithography, printing plates in digital printing are not regularly replaced. This significantly reduces the printing turnaround time and cost.

Digital printing allows for an amazing amount of variation and originality. For instance, wide format printers of up to 98″ width allow small businesses to print their output to heretofore unimagined sizes. Vinyl banner printing allows for production of vinyl banners up to 8 feet wide and up to 30 feet long. UV curable flatbed machines allow for printing directly on many surfaces from styrene to foamcore.

Inkjet and xerography are the most popular digital printing methods.

- Inkjet – It is a printing process that involves recreation of digital content by propelling small droplets of ink on a surface. Inkjet printers come in small, inexpensive devices and professional machines used on a range of surfaces such as papers, plastic, canvas, etc. The idea of inkjet printing was conceptualized in the 20th century but advanced extensively due to the development of computer technology.

- Xerography – Also referred to as electrostatic imaging, it is a printing technique based on electrostatic charges. The concept was invented and patented in the mid 20th century by Chester Carlson. An electrical charge is evenly distributed on a metal cylinder known as the drum to attract toner particles that are then transferred to the printing surface. Depending on the printing surface used, Xerography provides archival durability.

Gravure

Also known as rotogravure, it is a rotary printing technique where the content to be printed is engraved on a cylinder. Through high speed, the cylinder transfers the content on the printing surface. The method is mainly used in large volume works such as newspapers.

Here at the start of the 21st century, with new electronic printing methods emerging, there has never been a better time to explore the unlimited options that print technology brings you and your business.